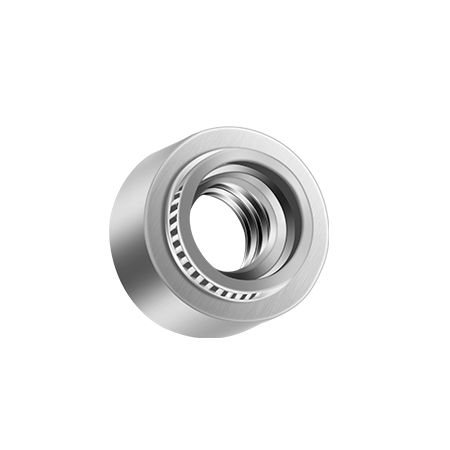

Pem Clinch Nut is a widely used fastener designed for metal sheet applications. It is embedded in pre-punched holes and secured to the sheet metal through a clinching process. Made from high-strength carbon steel or stainless steel, this nut offers excellent resistance to torsion and pull-out, providing a reliable threaded connection in thin sheets.

Pem Clinch Nuts are utilized in various industries such as automotive, electronics, communication devices, household appliances, and sheet metal processing. They are particularly suitable for applications where space is limited or installation is required from one side, ensuring stable and durable connections. The use of Pem Clinch Nuts can reduce the need for welding or other complex assembly processes, improve production efficiency, and ensure assembly quality and consistency.

Key Features

High-Strength Connection: Made from premium carbon steel or stainless steel, the Pem Clinch Nut offers excellent resistance to torsion and pull-out, ensuring a strong internal thread connection on thin sheet metal.

One-Sided Installation: Designed for installation from one side, making it ideal for space-constrained applications, simplifying the assembly process and saving time.

Reliable Anti-Loosening Performance: The clinching process tightly secures the nut to the metal sheet, preventing loosening and ensuring stability and reliability in long-term use.

Wide Application: Suitable for various industries such as automotive, electronics, household appliances, and communication devices, meeting the fastening needs of different sheet materials.

Excellent Corrosion Resistance: Stainless steel Pem Clinch Nuts offer superior corrosion resistance, making them ideal for use in harsh environments.

Application

Automotive Industry: Widely used in fastening body panels, chassis, and interior components, particularly where high tensile strength and reliable threaded connections are needed, such as in doors, dashboards, and seat structures.

Electronics: Used for securing circuit boards and enclosures, providing reliable grounding and shielding connections, ensuring the electrical performance and structural stability of the devices.

Communication Devices: In communication base stations, routers, and switches, Pem Clinch Nut is used to install and secure various internal modules and casing components, ensuring long-term stable operation.

Household Appliances: Applied in the metal sheet structures of refrigerators, washing machines, air conditioners, and microwaves, providing stable fastening and connection to ensure the overall durability of the appliances.

Sheet Metal Fabrication: Used in sheet metal fabrication and assembly processes for thin sheet connections, simplifying production and improving assembly efficiency, suitable for various metal materials.

Advantages

Durable Stability: The Pem Clinch Nut forms a strong internal thread connection with the sheet metal through the clinching process, preventing loosening and ensuring long-term stability of components.

Single-Sided Installation: Pem Clinch Nut can be installed from one side without the need for double-sided access, making it ideal for confined spaces or situations where the back is inaccessible, simplifying assembly and saving time and cost.

High Durability: Made from high-quality materials, Pem Clinch Nut offers excellent resistance to torsion and pull-out, and provides outstanding corrosion resistance in harsh environments, extending product lifespan.

Easy Integration: Suitable for a variety of thin sheet materials such as stainless steel, aluminum alloy, and copper, Pem Clinch Nut can be easily integrated into different designs and manufacturing processes, enhancing product versatility and flexibility.

Reduced Process Steps: By minimizing the need for welding or other complex fastening processes, Pem Clinch Nut significantly lowers assembly difficulty, improves production efficiency, and ensures high-quality assembly results.

Previous: Pem Self Clinching Nut

Next: Self Clinching Rivet Nut